Gephart Differentiators

When we're on the job, you're part of our family

At Gephart, we are your full-service electrical contractor known for combining major-league capabilities with a family-owned, personalized approach. We partner with you on every project from start to finish to ensure your needs are met the right way, on time and on budget. Our core values of quality, efficiency, and transparency all work together to make sure you know your job is our most important job. For our team, exceptional work is business as usual.

Our Differentiators

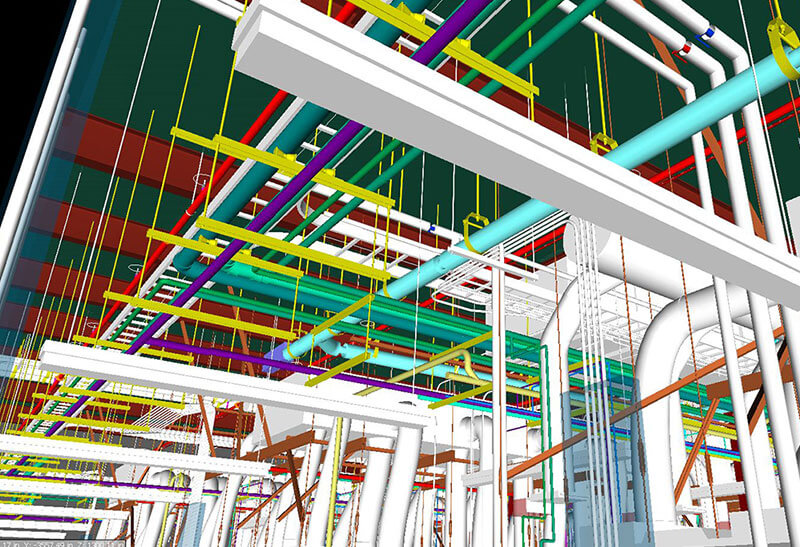

BIM/VDC

The proven edge of power

Gephart operates on the proven edge of industry technology, ensuring we’re capable of handling even the most complex or demanding requests efficiently and within budget. Our in-house BIM/VDC design department is highly trained and accredited which allows us to perform the majority of our projects on a design-build or design-assist basis. Our BIM/VDC team is well-versed in the latest design software and places great emphasis on producing for our clients with speed, intelligence, and accuracy. We invest time up front, identifying any conflicts during the design process so we can save time and money in the field. Our team also remains actively involved in industry events and conferences and maintains a spirit of continuing education throughout our process.

Benefits of our BIM/VDC services include:

- Coordination/clash detection saves time and money by correcting errors early before they become issues in the field

- Building Information Modeling (BIM) provides a clear project scope for our technicians to build to

- Total Station technology increases productivity by implementing modeling data throughout project

- Linked electrical information including quantity, circuit information, size, and manufacturer support procurement and maintenance efforts

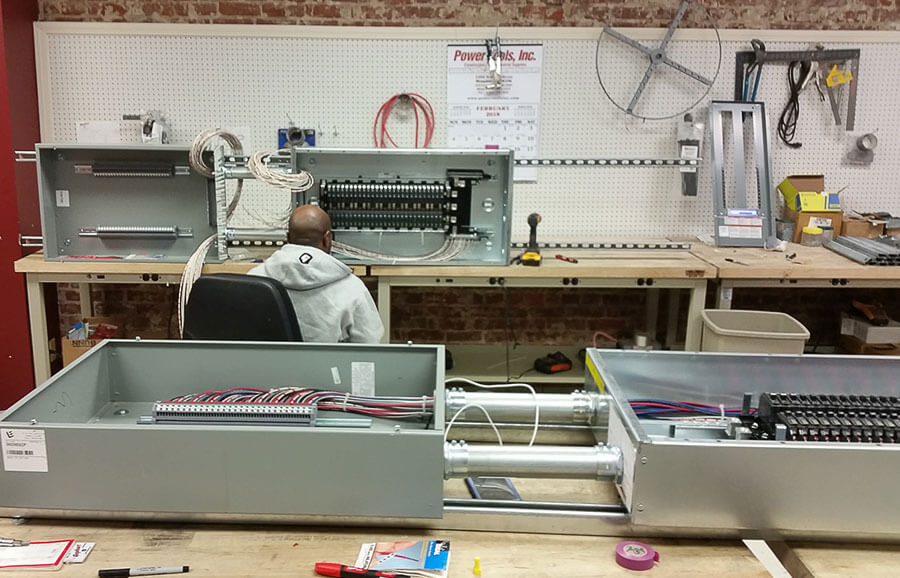

Prefab

Prefab capabilities to boost your largest projects

Our prefabrication services allow us to improve quality, safety, and efficiency on-site, and are especially beneficial on larger projects with a high number of repetitious assemblies. Our team excels in finding ways to reduce cost and accelerate the schedule across a wide range of job types by applying prefabrication techniques. There are numerous safety benefits to prefab work as well, as it reduces crews’ time spent on an active jobsite.

IPD/LEAN

Optimizing every job through LEAN strategies and IPD learnings

At Gephart, we practice LEAN construction processes that maximize the outcome and minimize lost time and money on every job, and our substantial IPD experience gives us an advanced understanding of how best to do so. Our goal is to optimize the results of the project from design through construction and to deliver as much value as possible to the owner. A responsive partnership is something we take seriously, not just for our clients, but for our colleagues as well.

Tech in Field

Industry leaders through every step of the process

Our proven-edge technology in the field allows us to complete every job on time and to the highest degree of quality. It plays a key role in our ability to shift gears quickly during a project and to adapt to the changing needs of our clients, whenever or however they arise. From start to finish, we’re here to partner with you and to deliver the most complete and effective electrical work in the industry.

Rope Access

Reaching new heights to serve our clients

Our rope access technicians use a rope and pulley system to access hard to navigate spots for construction, inspections, and repairs. Each rope technician has obtained specialized training through SPRAT (the Society of Professional Rope Access Technicians), the leading member-driven provider of education and training.

When done properly, rope access provides the following benefits:

- Safety: Rope access historically has higher safety records compared to traditional access methods.

- Efficiency: Technicians are able to set-up and tear-down all in a day’s work which leads to less disruptions and minimal downtime.

- Cost-Effective: In our industry, time is money. Smaller crews can get in and out without having to rely on coordinating heavy equipment, scaffolding, lifts, etc.